Ever wondered how leading enterprises most often complete projects on schedule and under budget? The key is Kanban Project Management! 🔑

Through visualizing processes and supporting continuous development, Kanban has transformed the way we work.

Studies 1 reveal that 87% of companies considered Kanban to be much more efficient than other project management methods.

David Anderson, a pioneer of the Kanban method 2, says, “Kanban provides a powerful framework for managing knowledge work, delivering high-quality results, and driving continuous improvement.”

This ultimate will help you to:

- Discover how to maximize your Kanban board’s setup to simplify your process.

- Examine case studies from successful companies.

- Hear from business leaders on Kanban’s benefits and drawbacks and how to negotiate them successfully.

Let’s get started!

What is Kanban?

The Japanese word “kanban,” meaning “visual signal” or “card,” describes a system of workflow management that emphasizes visualizing tasks to increase efficiency and foster a culture of constant improvement.

Improving production efficiency and minimizing waste, Kanban was developed from Toyota’s manufacturing technique in the late 1940s.3 It became quite popular in the healthcare and technology sectors in the 2000s after being modified for knowledge work and project management.

Key Principles of Kanban

- Visualizing Work:

- Create a Kanban board—a tool that displays tasks as cards on a board, with columns representing different stages of the process.

- Transparency allows teams to see the status of every task at a glance.

- Limiting Work in Progress (WIP):

- Set limits on the number of tasks in each stage.

- Helps maintain focus and prevent overload.

- Identifies bottlenecks and ensures smooth work progression.

- Managing Flow:

- Continuously monitor and optimize the process.

- Enhances efficiency and productivity.

Kanban’s simplicity and adaptability make it a powerful tool for project managers aiming to:

- Streamline processes.

- Enhance collaboration.

- Deliver high-quality results consistently.

Can Kanban Help with Continuous Workflow Improvement?

Kanban drives continuous workflow improvement by visualizing tasks, enforcing WIP limits, and enabling data-driven adjustments. A Kanban board makes bottlenecks visible, allowing teams to address issues swiftly to reduce cycle times.

By limiting WIP, your team prevents overload, leading to more predictable delivery and higher-quality outcomes. Regular reviews of metrics like lead time and cycle time provide insights for precise, iterative process improvements.

Effective implementation involves setting up distinct workflow stages on the board, defining and adjusting WIP limits, and conducting frequent retrospectives to refine practices based on real-time data.

Kanban vs. Other Methods

| Feature | Kanban | Scrum | Lean | Six Sigma | Critical Path | Waterfall |

| Delivery | Continuous, adaptable | Fixed-length sprints, iterative | Continuous, incremental | Continuous, data-driven | Clear timeline, less flexibility | Linear, sequential |

| Workflow | Visual board, stages | Iterative, regular reviews | Visual management, optimize workflow | DMAIC, statistical analysis | Task dependenc, strict scheduling | Stage completion required |

| Flexibility | High, changes anytime | Iterative development | Broad, across business processes | Adaptable to changing demands | Flexible, adaptable | Low, difficult changes |

| Focus | Continuous, scientific | Iterative development, regular reviews | Customer value focus | Defect reduction | Ongoing adjustments | Predictable, structured |

| Origin | Agile subset, visual work, limit WIP | Ongoing feedback & Improvement | Lean principles, waste reduction | Data-driven, statistical | Predictable, structured | Linear, sequential |

Before deciding on one, you need to know how Kanban differs from other well-known project management methodologies.

An analysis of Kanban in comparison to Waterfall, Scrum, Agile, Lean, Six Sigma, and Critical Path is presented here:

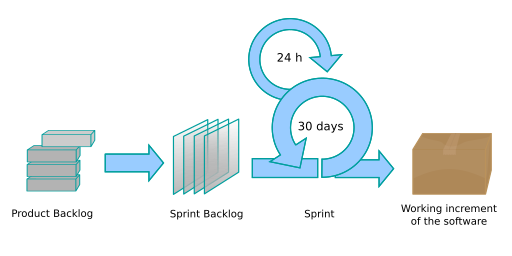

Kanban vs. Scrum

Kanban

- Continuous Delivery: Focuses on continuous delivery without fixed-length sprints, making it adaptable to changing priorities.

- Visual Management: Uses a visual board to manage workflow, with columns representing different process stages.

- WIP Limits: Emphasizes limiting work in progress (WIP) to prevent overload and ensure smooth workflow.

- Flexibility: Changes can be made at any time, allowing for a more flexible approach to project management.

Scrum

- Sprint Cycles: Operates in fixed-length sprints, typically 2-4 weeks, which helps plan and deliver increments.

- Defined Roles: Utilizes specific roles like Scrum Master, Product Owner, and Development Team to ensure clarity and accountability.

- Regular Reviews: Emphasizes iterative development with regular reviews and retrospectives to continually improve the process.

Read More: Scrum Project Management ✅ Guide for +800% Productivity

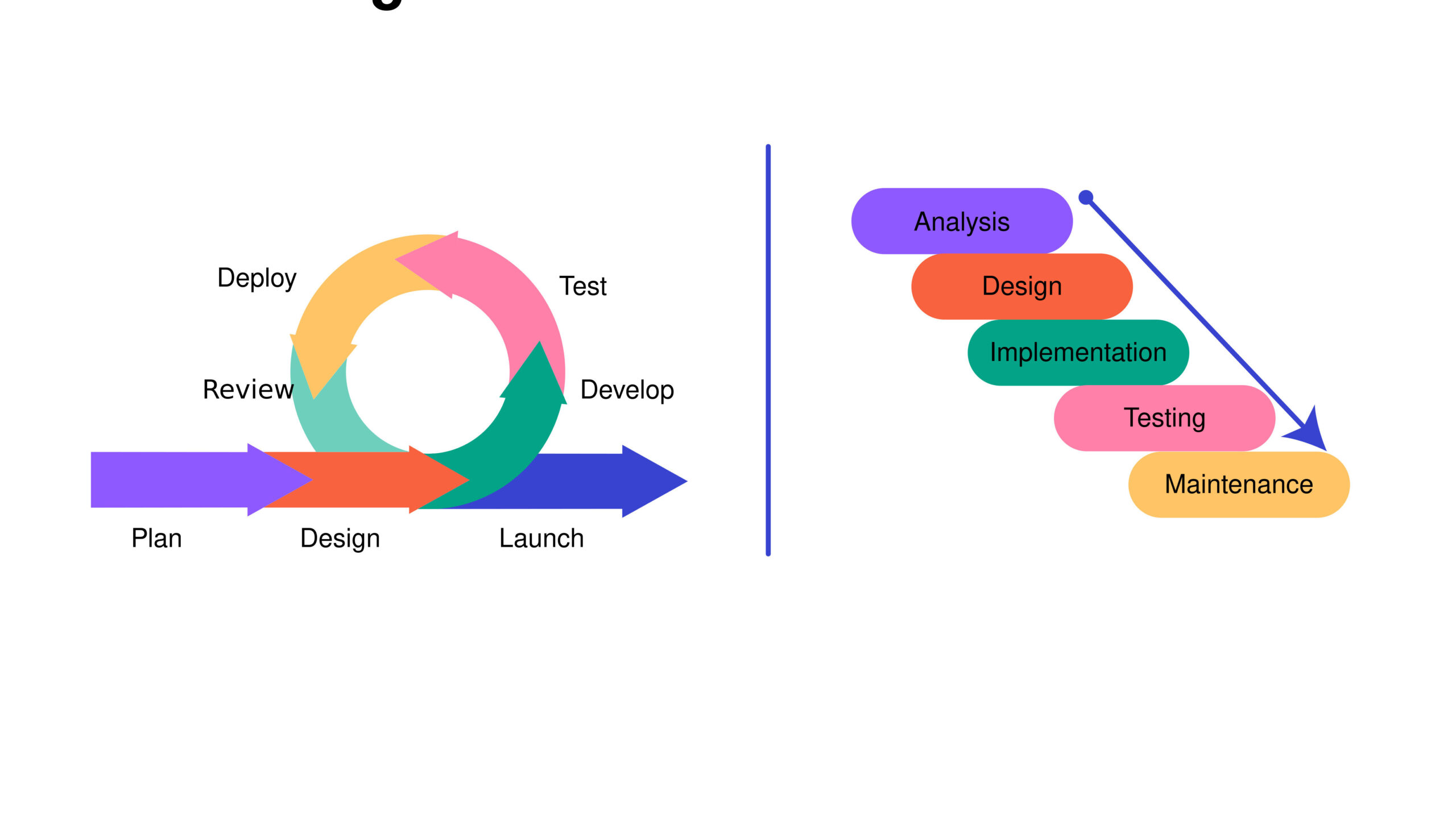

Kanban vs. Agile

Kanban

- Subset of Agile: Kanban is considered a part of Agile Project Management with a focus on visualizing work and limiting WIP.

- Process-Driven: Suitable for ongoing, process-driven projects where continuous improvement is key.

- Flow Management: Focuses on optimizing the flow of tasks through the system.

Agile

- Broad Philosophy: An overarching philosophy that includes frameworks like Scrum, XP, and others.

- Iterative Development: Focuses on iterative development, customer collaboration, and flexibility to change.

- Frequent Deliveries: Aims for frequent, incremental deliveries of product features.

Kanban vs. Lean

Kanban

- Lean Principles: Derives from Lean principles, emphasizing waste reduction and flow efficiency.

- Visual Management: Uses visual management techniques to optimize workflow.

- Incremental Improvements: Focuses on continuous, incremental improvements.

Lean

- Broad Application: A broader approach to maximizing value and minimizing waste across all business processes.

- Tools and Techniques: Involves tools like value stream mapping, 5S, and Kaizen for continuous improvement.

- Customer Focus: Strong emphasis on delivering value from the customer’s perspective.

Kanban vs. Six Sigma

Kanban

- Flow Management: Prioritizes visualizing work and managing flow to ensure efficiency.

- Incremental Changes: Continuous improvement through small, incremental changes.

- Flexibility: Adaptable to changing demands and priorities.

Six Sigma

- Defect Reduction: Focuses on reducing defects and variability in processes.

- DMAIC Methodology: Utilizes DMAIC (Define, Measure, Analyze, Improve, Control) methodology for process improvement.

- Data-Driven: Strong emphasis on data and statistical analysis to drive improvements.

Kanban vs. Critical Path

Kanban

- Flexibility: Flexible and adaptable approach with no fixed timelines.

- Visual Management: Manages flow through visual boards to ensure transparency.

- Continuous Improvement: Allows for ongoing adjustments and improvements.

Critical Path

- Task Dependencies: Identifies the longest task sequence that determines the project duration, focusing on strict scheduling.

- Scheduling Focus: Emphasizes strict scheduling and task dependencies to ensure timely project completion.

- Predictability: Provides a clear timeline for project delivery but lacks flexibility.

Read More: Critical Path Project Management: Save Time by 20% Guide ✅

Kanban vs. Waterfall

Kanban

- Iterative Approach: Incremental and iterative, allowing for continuous delivery and adaptation.

- Flexibility: Changes can be made at any stage, offering a high degree of adaptability.

- Visual Management: Uses visual boards to manage and optimize workflow.

Waterfall

- Linear Process: Linear and sequential approach with defined stages (e.g., requirements, design, implementation).

- Stage Completion: Each stage must be completed before moving on to the next, making changes difficult to implement later.

- Predictability: Provides a predictable and structured approach but can be inflexible.

Read More: Waterfall Project Management ✅ All You MUST Know

Key Kanban Principles

1. Visualizing Work

Kanban’s main concept is seeing the flow. Usually, a Kanban board shows all tasks as cards passing through several phases of the process, such as “To Do,” “In Progress,” and “Done.”

In a software development team for example, a Kanban board can feature columns for backlog, coding, testing, and deployment. This arrangement lets team members quickly view work status and identify areas where bottlenecks could develop.

2. Limiting Work in Progress (WIP)

Reducing the amount of ongoing work guarantees a seamless flow and prevents task overload. This idea highlights finishing current projects before beginning new ones.

WIP restrictions can help an engineering team improve its workflow and manage cross-departmental dependencies to limit the number of tasks in progress.

3. Managing Flow

Managing the flow includes closely monitoring the progress of tasks and constantly improving this method to guarantee effectiveness. This idea guides quick identification and resolution of issues.

Real-World Example: From strategy to execution, Schlenk, a chemical manufacturer, used Kanban to show their entire process. Thanks to this visual aid, their cycle time was shortened from 110 to 44 days 4, and inefficiencies were found.

4. Making Process Policies Explicit

Clearly defined and communicated process policies guarantee everyone understands the workflow. This transparency controls expectations and maintains consistency.

For example, a marketing team on their Kanban cards precisely specifies task categories and needs. This approach ensures that every team member is in line with what has to be done and prevents misunderstandings.

5. Implementing Feedback Loops

Daily stand-ups or retrospective meetings are two examples of regular feedback loops that enable your team to constantly evaluate their performance and make required changes.

For instance, Aerosud first instituted daily Kanban meetings in aerospace 5 to provide visibility into task status and communication. This exercise improved their efficiency and throughput.

6. Improving Collaboratively

Encouragement of ongoing development through scientific methods allows your team to fine-tune their procedures depending on empirical data.

Kanban Board: Visual examples with annotations of each component (columns, cards).

Read More: Project Management Fundamentals 💡 Essential Tips for Success

Step-by-Step Guide to Implement Kanban

Step 1: Set Up Your Kanban Board

Define Workflow

- Identify Key Stages: Start by defining the main phases of your task. Typical phases run “Backlog,” “In Progress,” and “Done.” Match these phases to your own project requirements.

- Visual Representation: Create your Kanban board on a physical whiteboard or using digital tools like Mirorim.

Create Kanban Cards

- Task Details: Create a card for every task, including a detailed description, assignees, due dates, and any relevant attachments. This guarantees easily accessible all required information.

- Prioritize Tasks: Organize your tasks by priority so that the team concentrates on the most important ones initially.

Step 2: Customize Your Board

Set WIP Limits

- Prevent Overload: Find the highest number of open tasks at every level. This will maintain a seamless flow and prevent team members from becoming overwhelmed.

- Balance Load: WIP restrictions should change depending on team capacity and workload to ensure a fair distribution of tasks.

Visual Management

- Use Visual Signals: Color-coded cards, tags, and icons show priority levels, task kinds, and deadlines on your board. This facilitates quick identification of task urgency and status.

- Custom Columns: You can customize columns to reflect particular steps in your process, such as “To Do,” “In Progress,” “Testing,” and ” Completed.”

Step 3: Adopt Kanban Practices

Regular Stand-Up Meetings

Run Daily Review to:

- Review the Kanban board.

- Go over advancements.

- Handle any obstacles in daily or weekly stand-up meetings.

These meetings provide actionable insights and immediate feedback, helping the team stay on track.

Read More: +100 Good Icebreaker Questions for Team Collaboration (Chosen by Experts) ✅

Continuous Improvement

- Incremental Changes: Based on performance metrics, inspire team members to add minor adjustments to the procedure. A fundamental principle of Kanban project management is constant improvement.

- Performance Metrics: Track key performance indicators (KPIs), including cycle time, lead time, and throughput, to identify areas of improvement.

Feedback Loops:

- Regular Retrospectives: Plan frequent retrospectives to evaluate both areas that need improvement and those that went well. These meetings should honor achievements.

- Adapt and Evolve: Prepare to change your Kanban board depending on feedback. Keeping a decent workflow depends on this adaptability.

Kanban Tools and Software

Implementing and maximizing your Kanban workflow depends on choosing the right tools for it. Here we will review the top pick, Mirorim!

Mirorim

Mirorim is a complete productivity tool meant to strike a harmony between team-care and project delivery. Teams wishing to apply Kanban project management while preserving an excellent work-life balance will find this the perfect fit.

Key Features

- Real-Time Chat and Collaboration: Mirorim provides robust communication features for teams to work efficiently together.

- Task Assignment and Tracking: With visual Kanban boards, easily assign tasks, create due dates, and track development.

- Self-Awareness and Well-being: A unique “Miroring” tool offers insights into work practices and emotional well-being, enabling teams to remain balanced and effective.

- File Sharing and Integration: Miorim faciliates file sharing and integrating with other commonly used programs.

Use Cases

- Technology Teams: Ideal for software development teams that need to oversee complex projects with continuous integration.

- Healthcare Projects: Perfect for managing healthcare projects where uptime, data security and performance are vital.

- Remote Teams: Perfect for remote teams needing robust tools for communication and collaboration to remain connected and effective.

Kanban Project Management Best Practices

1. Optimize WIP Limits Based on Data

Track and change your Work In Progress (WIP) limits depending on team capacity and real-time data. Correctly define WIP limits to provide a consistent workflow and help avoid congestion. Fine-tune these limitations using metrics, including cycle time and throughput.

tart with modest WIP restrictions and progressively change as you compile increasing performance data on your team. This approach shows inefficiencies in the workflow that demand attention and keeps team members from feeling overburdened.

For example, WIP helps a software development team enhance its process. This ensures a stable flow and helps to avoid congestion, drastically lowering project delivery times and raising general efficiency.

2. Implement Explicit Policies

Define and record policies for every level of your Kanban board.

Clear policies ensure that everyone knows the criteria for distributing tasks across stages, enhancing consistency and responsibility.

To make more sense, these rules should be obvious on the Kanban board and routinely examined. Have your team help you draft these rules to guarantee buy-in and compliance.

3. Use Class of Service for Prioritization

To properly prioritize work, sort tasks using several classes of service (e.g., Expedited, Fixed Date, Standard, and Intangible).

This guarantees that essential chores are completed immediately and helps control several kinds of labor with different degrees of urgency and effect. To keep clarity and efficiency, define particular guidelines and WIP limitations for every class of service.

Review how chores are distributed among these categories often to guarantee a fair burden and best use of resources.

4. Optimize the Kanban Board Layout

Create your Kanban board layout to fit your team’s workflow, providing extra clarity in sub-columns.

A well-designed board shows the real process, enabling team members to grasp the workflow and rapidly spot obstacles.

Swimlanes let you divide several kinds of work or tasks on the same board for greater organization. Make sure the design reflects changes in the process by means of regular updates and simplicity.

For a product development team, customizing the Kanban board with columns including “Backlog,” “Design,” “Development,” “Review,” “Testing,” and “Launched” can be pretty helpful. This provides a clear visual of every project step.

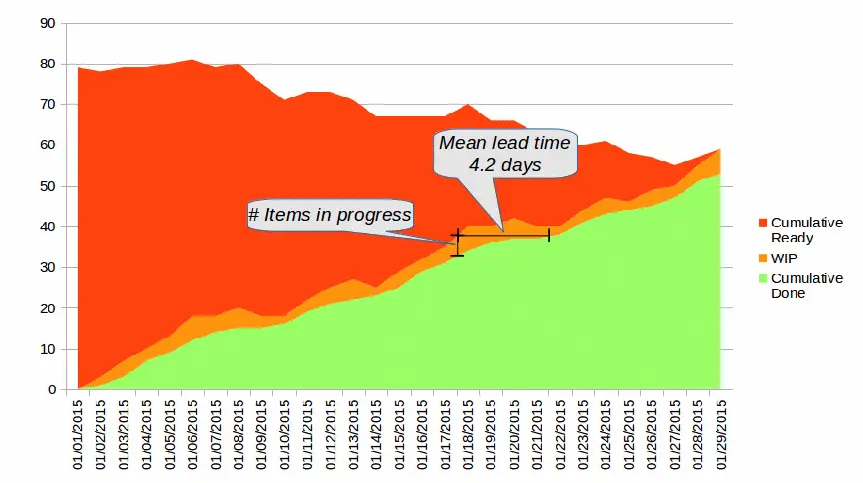

5. Leverage Cumulative Flow Diagrams (CFDs)

Examine cumulative flow diagrams often to track workflow and stability.

CFDs enable well-informed decisions to increase flow by providing insights into work in progress, cycle times, and bottlenecks.

Use CFDs to find trends and act early to fix process problems. Share these ideas with the staff to encourage a cooperative attitude to process enhancement.

For example, CFDs let you find tasks accumulating in the testing phase. They maximized the workflow by clearing this bottleneck, ensuring that jobs passed through each stage without delay.

6. Establish Feedback Loops

Incorporate daily stand-ups, weekly reviews, and retrospectives among regular feedback loops into your approach.

Constant feedback enhances team alignment, helps spot early problems, and stimulates ongoing development. Make sure feedback meetings follow a disciplined agenda with an eye toward practical ideas.

Promote honest communication and make sure comments result in real process enhancements.

7. Visualize Blockers and Dependencies

On your Kanban board, visualize dependencies and blockers to show challenges stopping task completion.

Early identification and resolution of obstacles give you a more seamless workflow that lower delays. Indicate blocked chores and dependencies using different visual signals, including colored flags or icons. Review these visual indicators often, then act to fix problems.

8. Implement Kaizen for Continuous Improvement

Adopt the Kaizen approach by pushing little, gradual improvements to keep processes always better.

Constant improvement helps your team change with time and progressively raise output and quality. Encourage team members to regularly propose and carry out enhancements, promoting a learning culture. Track these adjustments to evaluate their success.

9. Utilize Swimlanes for Workflow Segmentation

Use swimlanes to segment your team, project, and associated tasks. This lets you clearly view workflows and facilitates proper management and balancing of priorities. Make swimlanes fit for your team structure and particular project requirements.

For instance, swimlanes allow a content marketing team to divide their Kanban board into several content categories, such as blogs, videos, and infographics.

10. Monitor and Adapt Flow Metrics

Track important flow metrics, including lead time, cycle time, and throughput, constantly.

Monitoring these indicators clarifies the performance of your team and points up areas needing work. Set reasonable objectives using these criteria and track development.

Review these indicators often with your staff to encourage a data-driven improvement method.

To evaluate performance, a software development team might examine cycle time and throughput. Analyzing these indicators helps one to find areas for development and modify their approach, enabling faster delivery and increased production.

Common Mistakes to Avoid

1. Ignoring WIP Limits

Many teams set Work In Progress (WIP) boundaries but then overlook them under increasing strain.

Impact: Less effectiveness and overloaded team members.

Solution: Strictly enforce WIP rules and apply them to spot capacity limitations and bottlenecks. To better control the workload, the aerospace manufacturer Aerosud used WIP restrictions; this improved team capacity and communication, increasing the throughput from 60 to 120 tickets within three days.

Read More: How To Define Boundaries In a Project ⛔

2. Lack of Explicit Policies

Teams sometimes overlook the need to clearly define specific policies for assigning tasks across phases.

Impact: This results in inconsistencies and misunderstandings about task progress.

Solution: For every level of the Kanban board, clearly record and explain policies. Review and upgrade these rules often.

3. Poorly Defined Workflow Stages

Defining either too few or too many workflow stages or stages that do not mirror the real process is a mistake.

Impact: Confusion and ineffective task management

Solution: Match the workflow to your team’s real procedure. For instance, ULMA Handling Systems 6 tailored their Kanban board to show certain project requirements, hence enhancing visibility and communication.

4. Neglecting Regular Reviews and Feedback Loops

Skipping stand-ups, retrospectives, and regular reviews is a mistake.

Impact: This compromises the timely identification of problems and ongoing development.

Solution: Including regular feedback loops in your process can help you examine development, fix problems, and promote ongoing learning. Try fresh ideas and strategies to embrace the iterative character of improvement.

5. Overloading the Board with Too Many Tasks

Stuffing too many chores onto the Kanban board at once.

Impact: This strains the staff and lowers output and attention.

Solution: To guarantee a reasonable workload, prioritize tasks, and take advantage of WIP restrictions. Try to finish tasks before introducing other ones.

6. Inadequate Use of Visual Signals

Ignoring visual signals like color-coded cards, tags, or icons is a mistake.

Impact: This makes it challenging to evaluate job priorities and state swiftly.

Solution: Use clear visual signals to indicate task priority, status, and obstructions. Change these signals often to represent current conditions.

7. Ignoring Bottlenecks and Blockers

One mistake is not supporting a constantly improving culture.

Impact: This might stop advancement and sour team morale.

Solution: On the Kanban board, see blocks and dependencies; act immediately to fix them.

8. Lack of Continuous Improvement (Kaizen)

Not encouraging a culture of continuous improvement.

Impact: This leads to stagnation and missed opportunities for process enhancements.

Solution: Encourage team members to routinely propose and carry out little, gradual enhancements under a Kaizen culture.

9. Misuse of Metrics and Data

Misusing metrics and data, such as not using or neglecting measurements like cycle time, lead time, or throughput, is a mistake.

Impact: This makes performance evaluation challenging and helps one to spot areas for improvement.

Solution: Track and evaluate important benchmarks to direct decisions. Establish reasonable objectives using facts, then track development.

10. Lack of Team Buy-In

Using Kanban project management without first ensuring complete team buy-in and involvement is a mistake.

Impact: This can cause low adoption rates, opposition, and poor Kanban system use.

Solution: Involve the team in the implementation process, offer training, and routinely get feedback.

Real-world Case Studies

ULMA

ULMA Handling Systems 7, a Spanish engineering firm, specializes in developing automated intralogistics solutions. These projects are inherently complex, involving extensive cross-departmental coordination and compliance with strict regulatory standards.

Challenges: The primary issues were a lack of visibility into work processes, inefficient communication, and extended delivery times. The intricacy of their projects often led to misunderstandings and delays.

Solution: ULMA adopted Kanban boards and regular cadences (structured meetings) to enhance transparency and streamline communication. Explicit Kanban policies were also defined to standardize workflows.

Outcome: Post-implementation, ULMA saw a significant reduction in project delivery times. The improved visibility into workflows helped identify bottlenecks early, allowing for timely interventions. Communication across departments improved, leading to a more synchronized operation. Notably, their project delivery increased by 30%, and delays were cut by 50%.

Schlenk

Schlenk, a chemical manufacturer 8, aimed to enhance its R&D project management by improving transparency and efficiency.

Challenges: Inefficient handoffs between teams, limited visibility into process blockers, and a lack of clear performance metrics were major headaches. These often resulted in delayed project timelines and inconsistent output.

Solution: Using Kanban project management, Schlenk visualized their entire workflow, identifying and addressing bottlenecks. They adopted interconnected Kanban boards using the Flight Levels concept to manage work from strategy to execution.

Outcome: The transformation reduced cycle time from 110 days to 44 days. Communication and workflow efficiency improved significantly, with clearer task assignments and faster issue resolution. Additionally, the overall project success rate improved by 40%, highlighting Kanban’s effectiveness in optimizing project management in the chemical industry.

Aerosud

Aerosud, an aerospace manufacturer 9, needed to enhance the management of its engineering projects and IT tasks while complying with strict regulations.

Challenges: The main issues included rigid processes, regulatory compliance, and inadequate team communication and capacity management. These factors often led to project delays and inefficiencies.

Solution: The IT division at Aerosud introduced Kanban boards and implemented work-in-progress (WIP) limits, along with daily meetings to improve visibility and communication.

Outcome: The IT division’s throughput doubled from 60 to 120 tickets within 3 days. This improvement in the IT sector spurred broader adoption across engineering projects. The enhanced visibility and communication led to better capacity management and quicker resolution of bottlenecks, reducing project timelines by 25%.

GE Aviation Czech

GE Aviation Czech 10 was engaged in a high-stakes aircraft engine development program that required precise coordination and clear prioritization.

Challenges: The team faced overwork, unclear priorities, and a lack of direction, leading to inefficiencies and delays.

Solution: Kanban project management allowed GE Aviation Czech to visualize their workflow comprehensively. They set up Kanban boards to track tasks through various stages, from backlog to deployment.

Outcome: The introduction of Kanban improved efficiency significantly. The clear visualization of tasks helped the team prioritize and manage their workload more efficiently. This led to a 20% reduction in project delivery times and a 15% increase in team productivity.

Expert Insights

“Kanban promotes transparency by making the entire workflow visible to all team members. This visibility helps identify bottlenecks or issues early, allowing for timely resolutions and smoother project progress.” – Esther Cohen, Workamajig.

“Kanban benefits your team by encouraging frequent collaboration. From organizing daily priorities with stand-up meetings to strategic reviews, all team members are constantly encouraged to work together and share their insights on improving current processes.” – Sonya Siderova, Nave.

“All we are doing is looking at the timeline from the moment the customer gives us an order to the point when we collect the cash. And we are reducing that timeline by removing the non-value-added wastes.” – Taiichi Ohno, the father of the Toyota Production System (TPS)

“The most efficient and effective method of conveying information to and within a development team is face-to-face conversation.” – Mary Poppendieck, co-author of Lean Software Development: An Agile Toolkit

“Kanban is not a process. It’s a way to improve your process.” –Eric Brechner, author of Agile Project Management with Kanban.

“Kanban is a method for defining, managing, and improving services that deliver knowledge work, such as professional services, creative endeavors, and the design of both physical and software products.” –Mike Burrows, author of “Kanban from the Inside,

Conclusion

- Kanban views whole workflows, which helps one to find bottlenecks and simplify procedures.

- Setting WIP limits helps teams avoid overload, keep concentration, and enhance task flow by controlling their workload.

- Managing flow by constant improvement increases general productivity and efficiency.

- Explicitly create process policies. Well-defined policies guarantee everyone’s understanding of the workflow.

- Using feedback loops—regular comments via stand-ups and retrospectives—allows for ongoing development.

- Encourage teamwork and apply scientific techniques to propel process enhancements grounded on empirical facts.

- Kanban guarantees that every team member helps to improve processes through regular participation. Organizations implementing Kanban project management find notable increases in efficiency and productivity; some claim up to a 30% rise in productivity and a 50% drop in project lead times.

Interested in Kanban?

Try Mirorim’s Kanban tool for free to experience firsthand how it can optimize your project processes. Create your FREE account today and take the first step towards perfectly efficient and productive workflows.

FAQ | Kanban Project Management

Visualize Work: Use a Kanban board to display tasks and workflows.

Limit Work in Progress (WIP): To avoid bottlenecks, set limits on the number of tasks in progress.

Manage Flow: Continuously monitor and optimize the flow of tasks through the system.

Make Process Policies Explicit: Clearly define and communicate process policies to ensure everyone understands the workflow.

Implement Feedback Loops: Use regular meetings like stand-ups and retrospectives to review progress and make improvements.

Improve Collaboratively, Evolve Experimentally: Encourage ongoing development and continuous improvement through scientific methods and empirical data.

Visual Signals: Use cards or tickets to represent tasks on a Kanban board.

Columns: Create columns on the Kanban board to represent different stages of the workflow.

WIP Limits: Set limits on the number of tasks in each stage to prevent overload.

Commitment Point: The stage where tasks are committed to be completed.

Delivery Point: The final stage where tasks are considered complete and delivered.

Kanban: Focuses on continuous delivery, visual management, and flexibility with no fixed-length sprints. Emphasizes WIP limits and allows changes at any time.

Scrum: Operates in fixed-length sprints (typically 2-4 weeks) with defined roles (Scrum Master, Product Owner, Development Team) and regular reviews. Emphasizes iterative development and incremental deliveries.

Kanban: A subset of Agile that emphasizes visualizing work, limiting WIP, and managing flow. Suitable for ongoing, process-driven projects.

Agile is an overarching philosophy that includes frameworks like Scrum, XP, and others. It focuses on iterative development, customer collaboration, and flexibility.

Kanban is considered part of Agile methodologies due to its focus on continuous improvement and flexibility. It is not related to the linear and sequential approach of the waterfall method.

No, Kanban is not a Six Sigma. While both focus on process improvement, Six Sigma aims to reduce defects and variability through a data-driven approach. In contrast, Kanban focuses on visualizing work and managing flow for continuous improvement.

The basic Kanban formula involves visualizing tasks on a Kanban board, setting WIP limits, and managing the flow of tasks to ensure efficiency and continuous improvement.

Kaizen is a Japanese term meaning “continuous improvement.” It involves making small, incremental changes to processes to improve efficiency and quality over time.

Kanban is a visual system for managing work as it moves through a process. It uses cards and boards to represent tasks and stages, helping teams see the status of work and identify bottlenecks.

An example of a Kanban system is a software development team using a Kanban board with columns for “Backlog,” “In Progress,” “Testing,” and “Done,” with tasks represented as cards moving through these stages.

Set Up Your Kanban Board: Define workflow stages and create Kanban cards with task details.

Customize Your Board: Set WIP limits and use visual signals like color-coded cards.

Adopt Kanban Practices: Conduct regular stand-up meetings and continuous improvement cycles.

Kanban for beginners involves setting up a simple board with columns like “To Do,” “In Progress,” and “Done.” Start with a few tasks, set WIP limits, and focus on visualizing work and managing flow.

Kanban is part of Agile methodologies, focusing on continuous improvement and flexibility. It differs from Scrum, which operates in fixed-length sprints with defined roles and regular reviews.

Kanban is considered both Lean and Agile. It derives from Lean principles, emphasizing waste reduction and flow efficiency, and is also part of Agile due to its focus on continuous improvement and flexibility.

No, Kanban does not have fixed-length sprints. It focuses on continuous delivery and allows changes to be made at any time.

No, Kanban is not a waterfall. Kanban is an Agile methodology focusing on continuous improvement and flexibility, unlike the linear and sequential approach of the waterfall method.

Yes, Kanban often includes daily stand-ups to review progress, discuss any issues, and plan the day’s work.

No, there is no defined role of a Scrum Master in Kanban. Kanban teams typically manage their own workflow without specific roles like in Scrum.

Kanban uses tasks, which can include user stories, bug fixes, or any work items represented on Kanban cards.

While Kanban does not have prescribed ceremonies, it often includes regular meetings like daily stand-ups and retrospectives to review progress and identify improvements.

Creating a Kanban Board: Define columns for different workflow stages.

Using Kanban Cards: Represent tasks as cards on the board.

Setting WIP Limits: Limit the number of tasks in each stage to maintain flow.

A real-life example of Kanban is a manufacturing company using a Kanban board to visualize production stages, from raw materials to finished goods, ensuring efficient workflow and timely delivery.

Sticky notes on a Kanban board represent tasks and move through different stages (columns) as work progresses. They provide a visual representation of the status and flow of work.

References

- STATE OF KANBAN REPORT 2022. (2022). In Kanban.University/State-of-kanban. https://kanban.university/wp-content/uploads/2022/10/State-of-Kanban-Report-2022.pdf ↩︎

- Kanban for Creative Knowledge Work: D.J. Anderson Interview | Kanban Library. (n.d.). Kanban Tool. https://kanbantool.com/kanban-library/why-kanban/kanban-for-creative-knowledge-work ↩︎

- Kanban made simple : demystifying and applying Toyota’s legendary manufacturing process in SearchWorks catalog. (n.d.). https://searchworks.stanford.edu/view/13513711 ↩︎

- 6 Real-World Kanban Examples with Proven Results. (n.d.). Kanban Software for Agile Project Management. https://businessmap.io/blog/kanban-examples ↩︎

- 6 Real-World Kanban Examples with Proven Results. (n.d.). Kanban Software for Agile Project Management. https://businessmap.io/blog/kanban-examples ↩︎

- Orchestrate Complex Projects by Means of Simple Practices. (2021). In CASE STUDY. BERRIPOCESS. Retrieved August 13, 2024, from https://businessmap.io/wp-content/uploads/website-images/case-studies/Case_Study_ULMA.pdf ↩︎

- Orchestrate Complex Projects by Means of Simple Practices. (2021). In CASE STUDY. BERRIPOCESS. Retrieved August 13, 2024, from https://businessmap.io/wp-content/uploads/website-images/case-studies/Case_Study_ULMA.pdf ↩︎

- How a Chemical Company Improved its R&D Projects Performance. (2021). In Businessmap. Retrieved August 13, 2024, from https://businessmap.io/wp-content/uploads/website-images/kanban-resources/Case-studies/Case_Study_Schlenk-final.pdf ↩︎

- Enhancing Engineering Project Portfolio Management & Accelerating Digital Transformation in the Aerospace Industry. (2021). In CASE STUDY (pp. 1–4). Businessmap. https://www.xuviate.com/bootcamp/ ↩︎

- Lean Team Boosted Its Productivity During New Aircraft Engine Program. (2021). In BUSINESSMAP. Retrieved August 13, 2024, from https://businessmap.io/wp-content/uploads/website-images/kanban-resources/Case-studies/GE-Case-Study_NEW.pdf ↩︎